Aluminium and stainless steel are notoriously known to corrode when combined. This is especially the case when in an offshore environment. It therefore might shock a few people when we proudly state that our stainless-steel gate closing hinge is used on aluminium gates offshore.

In this blog, we will examine what galvanic corrosion is, how it affects aluminium and stainless steel, and what we do to prevent it on our offshore gate hardware.

What is galvanic corrosion and how does it happen?

Galvanic corrosion occurs between two dissimilar metals when subjected to an electrolyte.

The chemical process transfers electrons from the positively charged material (anode) to the negatively charged material (cathode). This is facilitated through a conducting electrolyte, such as water.

The electrons from the anode will start to transfer to the cathode, causing the anode to disintegrate or corrode. Certain electrolytes will speed up this process because they are low resistance. Salt water is one of these low resistance electrolytes, which is why you have to consider your materials even more in marine environments.

When the electrons move from the anode to the cathode, the anode material is weakened as it basically dissolves into the electrolyte. This can also cause the cathode to have a slight prolonger life span.

Galvanic corrosion offshore

With the constant presence of salt water, galvanic corrosion is an even bigger concern on any offshore application.

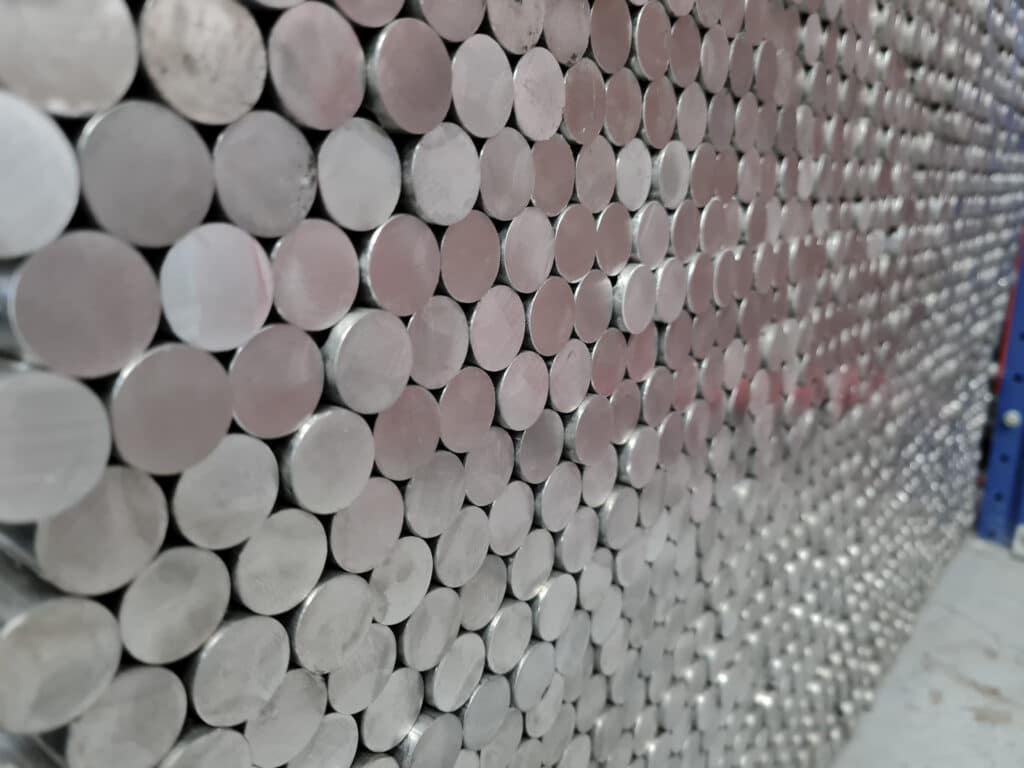

Aluminium gates are often used on the platforms as they are lighter and an easy material to work with. Our gate hardware is made from stainless steel, a metal that is dissimilar to aluminium and will speed up the corrosion process.

So, why would we choose to use stainless steel for our gate hardware?

Why we use stainless steel for our offshore hardware

A main question we get about our solutions is why we don’t use aluminium or a similar metal for our gate hardware. And there are two very simple reasons why: strength and durability.

Aluminium is a preferred metal to use for offshore gates, but it should be noted that the material will be subject to galvanic corrosion even without the presence of stainless steel. When subjected to the electrolytic salt water, aluminium and most other metals will corrode over time. Adding stainless steel to the equation simply speeds up the process.

We don’t use aluminium for the gate closing hinge because it wouldn’t be strong enough to function properly. With the strong forces at play, our hinges first and foremost have to be strong to ensure reliability. In addition, stainless steel in the correct grade (like 316L or duplex) will have high corrosion resistant properties.

Using stainless steel allows us to guarantee this durability. We therefore take other precautions to prevent the corrosion from happening.

How to prevent galvanic corrosion between aluminium and stainless steel

The best way to stop galvanic corrosion is to use metals with similar properties or simply use the same material. When this isn’t possible, like in our case, the main way to prevent galvanic corrosion is to make sure the two metals aren’t in contact with each other.

One way to stop our stainless-steel hinges and hardware from getting in contact with the bare aluminium, is with isolation.

For the gate closing hinge, we use an isolation pad made from HDPE to prevent direct contact with the aluminium gate.

To protect our other hardware (like our hatch hardware) and the platforms, we always use washers and isolation plates. When a stainless steel bolt has to be fixed to an aluminium gate or railing to fit the hinge, we use isolation sleeves.

Other isolation materials includes nylon or rubber (like EPDM).

Another common way to protect the materials is to treat them. This includes galvanising, plating, passivating, or powder coating the metal.

These treatments cover the metal and prevent contact between the two dissimilar metals.

Commonly, aluminium gates on offshore platforms aren’t powder coated, but will be galvanised or plated to create a sacrificial layer to protect the metal.

For our stainless-steel hinges, we pickle and passivate all components before assembly to further protect from corrosion.

Conclusion

Here at Gatemaster Offshore, we understand the risks of using dissimilar metals in an environment that has a high concentration of electrolytes like salt water. We therefore combine the use of isolation plates and washers with pickling and passivating our stainless steel. This allows us to use the gate closing hinges on aluminium gates.

Galvanic corrosion remains a main concern for us and our customers, and we are therefore always making sure our solutions will work for your specific gate configuration and materials.

If you would like more information on how we prevent galvanic corrosion between dissimilar metals, get in touch now.